Last rev: 10/23/2017 1:49:18 PM

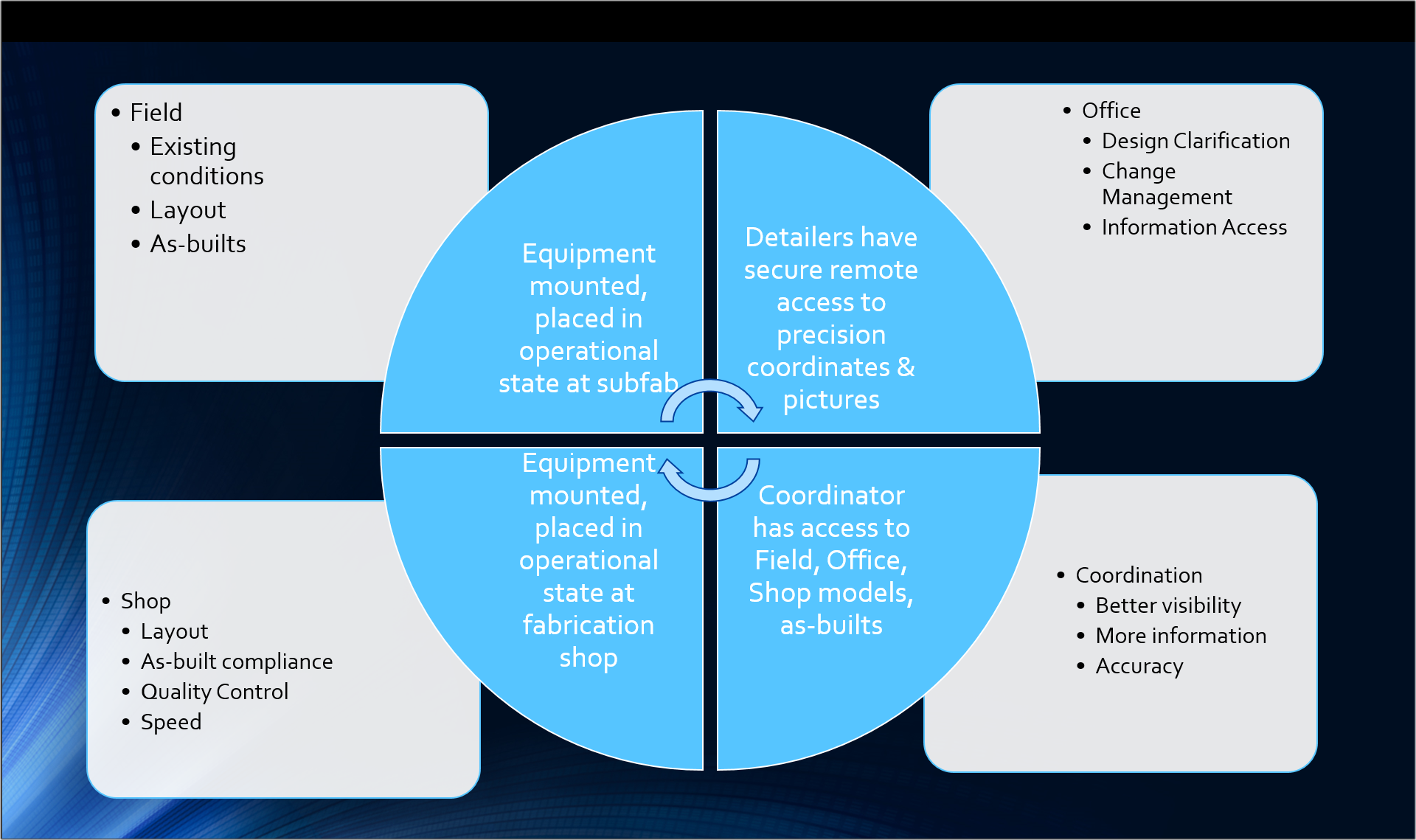

Information Access.[STATIC IMAGE]

Graphic Narrative

The present methods of determining utility (process, electrical, ducting) routing for Tool Install (AKA TI) utilizing laser scanning, field walks, and hand methods, can be improved. Specifically, improve measurement accuracy of existing conditions, provide layout, precise measurements of Points of connection, measuring completed shop fabrication and subfab as-builts, with communication between stakeholders.

Laser scanning, even the lower cost, easier to use, Leica Blk360s are unable to provide the precision, layout, and shear speed and operational capabilities of multiple Leica 3D Distos (AKA Droids) mounted to the unistrut around the working functional area.

Droids deployed to fab shops can provide layout data. The new workflow will not replace Laser scanning, which has value and provide a trade contractors a familiar routing process. We provide what laser scanning cannot technologically or realistically provide. Notably, Precision coordinates, speed, non-line-of-sight measurements, remote control access, use by multiple parties, small file size, no post registration of data, on-demand use, layout for fabricators and field trades, to mention most but not all.

We enable functional area teams additional access to subfab conditions, precison layout in fab shop or subfab. The same Droid that provides, measurements, pictures and coordinates, can provide layout data in subfab or trade fab shop. It can validate correct geometry in the subfab or fab shop.

With modification, Droids can be accessed remotely and securely 24 hours a day.

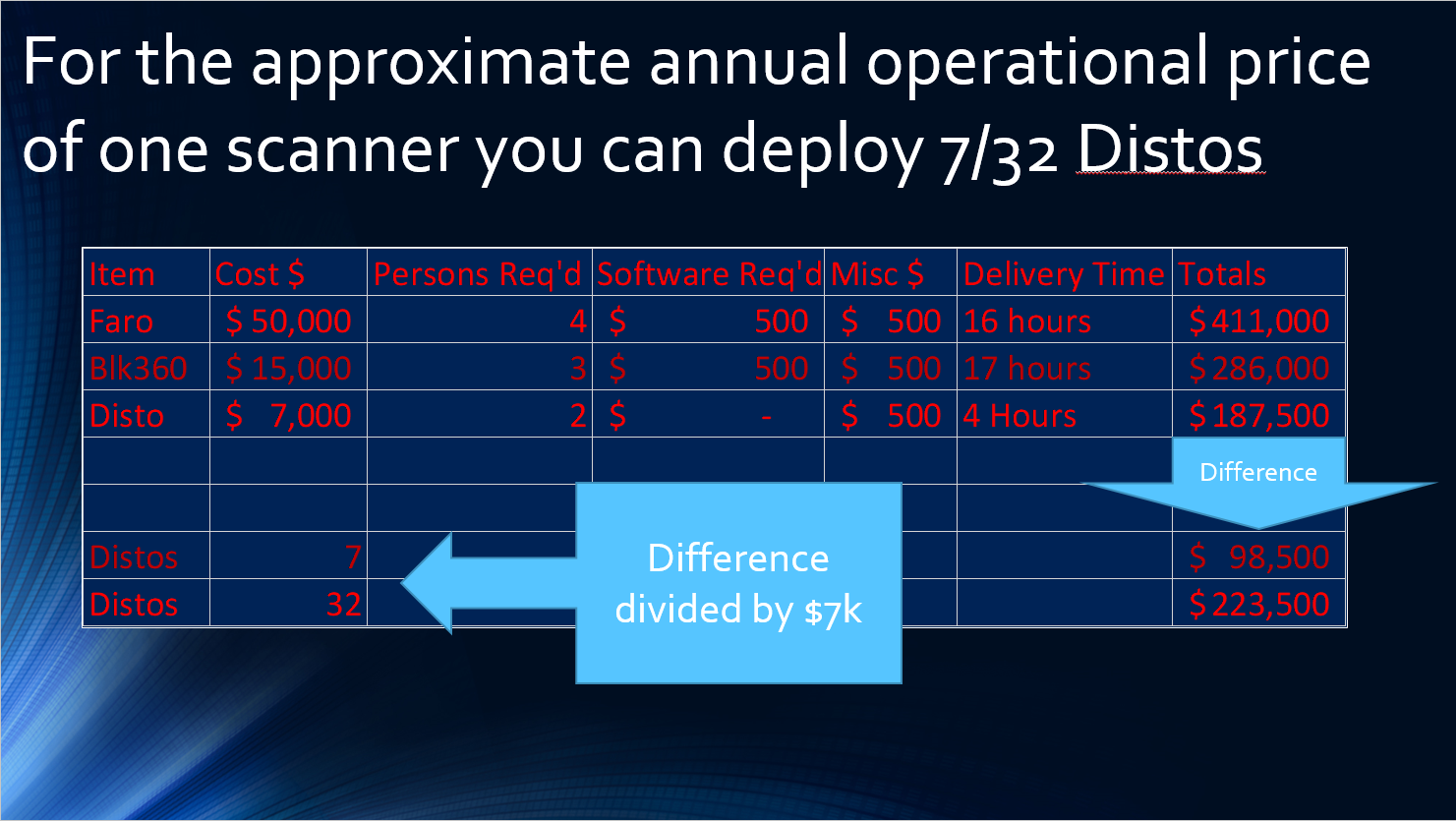

Costs.[STATIC IMAGE]

Graphic Narrative

Generally the cost of laser scanning, field walks, and hand measurements, are known. Metrics show the value of deploying Droids. Any laser scanning will require setup, operation, post processing (registration) and transfer of data before trade contractors can route. Laser scanners require more people to operate them. They normally are not left in place for days at a time and operated remotely by the functional area teams.

Laser scanners cannot provide layout points, nor transfer subfab geometry directly to the trade shop floor in seconds.

The Droid solution allows multiple units to be mounted all around the tool or functional area. They can provide information to any team member remotely via login. If a detailer needs some geometry, some measurements they login, locate the Droid in the area, and via the camera remote control interface take their own measurements. Their effective range is 500 mm (19 in.) to 50 meters (164 ft.).

For new installation layout the Droid can provide hanger, pipe, duct, wire way or other design element locations. After installation, objects can be measured to validate they are located per the coordinated models.