Intel Corporation

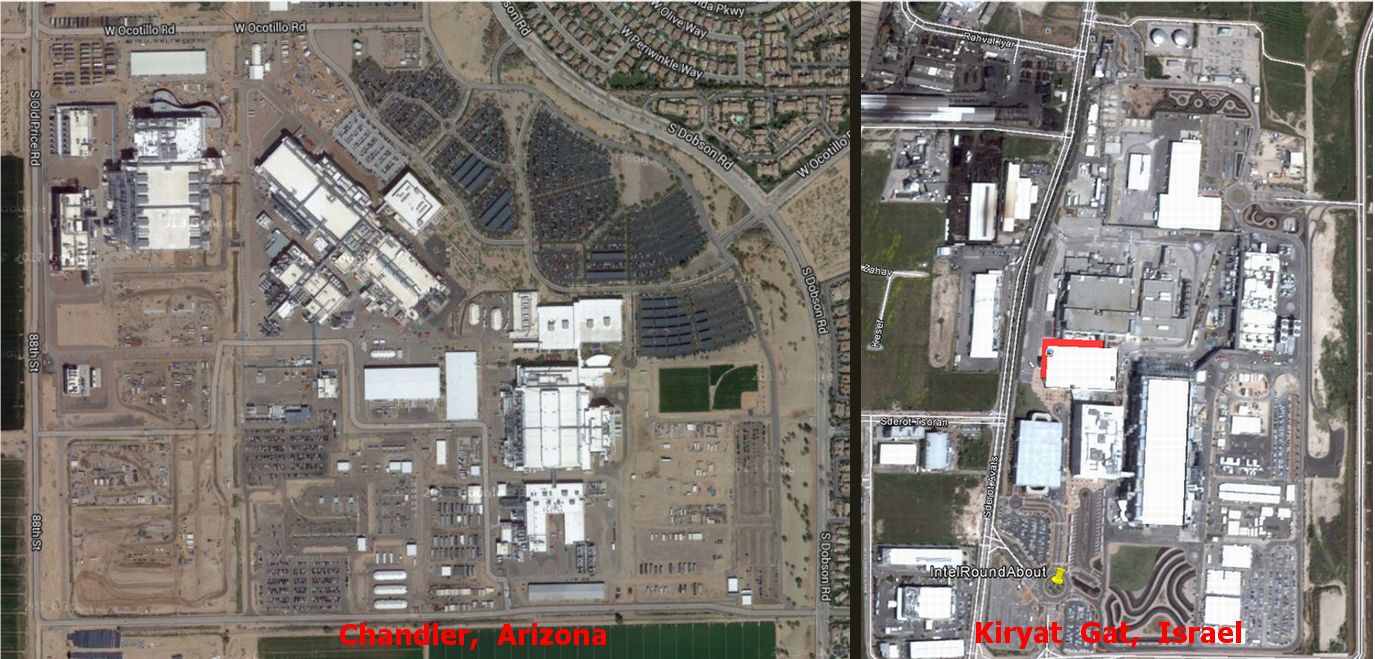

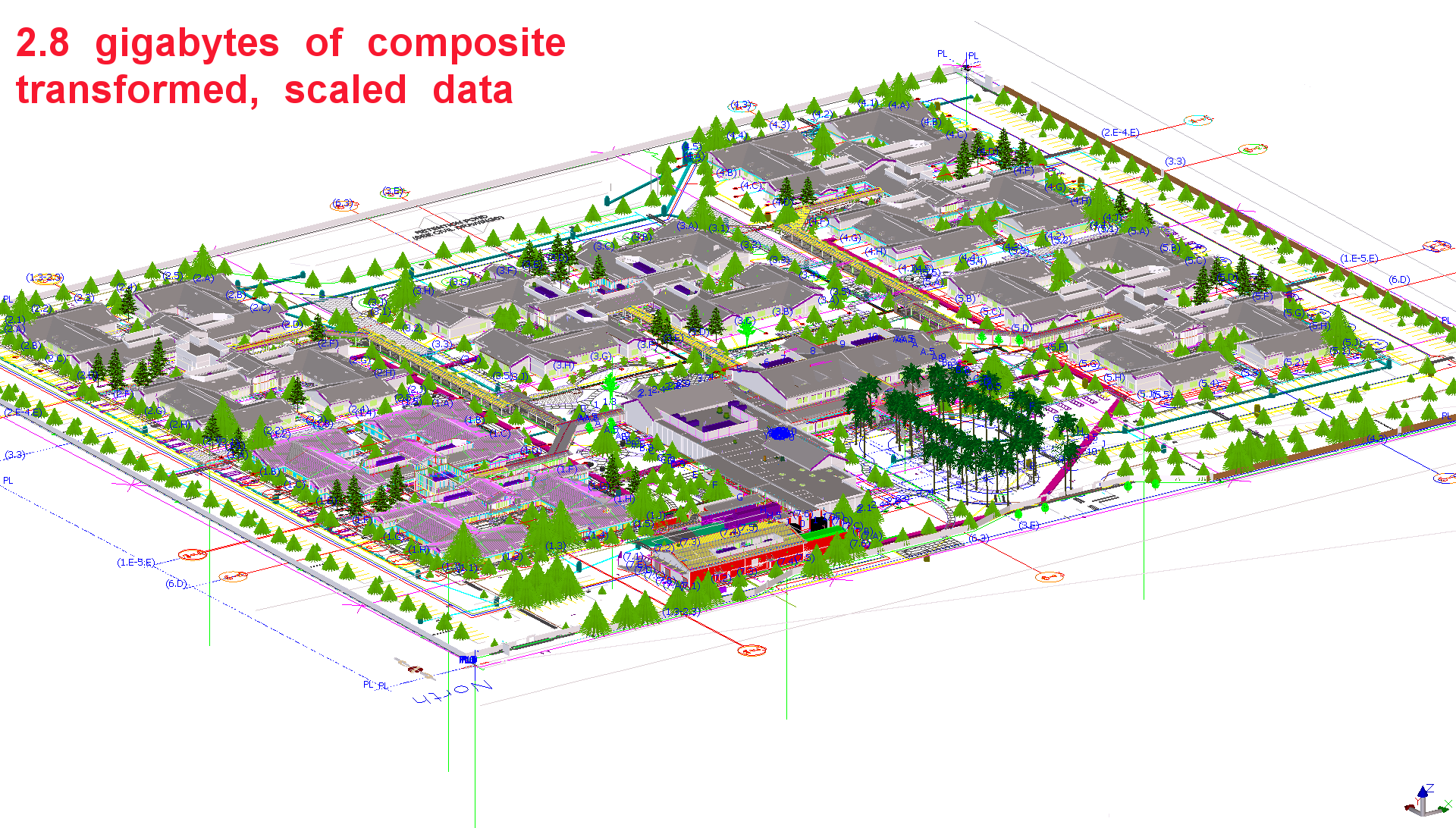

April 2012 through 2015 Lucrosol worked with Hensel Phelps Construction Company to provide a Intel corporation Virtual Design & Construction and Building Information Management services for their Ocotillo manufacturing plant in Chandler Arizona, and Kiryat Gat, Israel.

Every eighteen months the company replaces, or upgrades their semiconductor fabrication plants worldwide. This is referred to as Tool Install. The reader should accept that virtually all facts surrounding this project is considered Confidential. As such exacting details can at times be elusive. That aside the numbers provided are staggering. The production schedules and trade subcontractor accomplishments indeed impressive by any standards.

Some project metrics: Project site is 725 acres. Building acreage 50.3 (LCE 2.6, Fab 12 16.5, Fab 22 7.5, Bridge 2.5, Fab 32 10.3, Fab 42 11) There are four main project federated models, each averages 500 megabytes. Navis Manage When combined into a single project model the file is 3.1 gigabytes. Navis Manage The 3.1 gig model contains 1.8 billion entities. Yes we can load and view this single file.

There are over 136,000 laser scans. We track these laser scans with a Lucrosol innovation, a Laser Scan Identification Module program, which allows trade contractors to locate the scan they need. There are over 250 types of piping systems. Multiple types of 3D and laser scan software were used daily, the main software in use in Navis Manage. In my forty year career I have never seen or heard of a more technically challenging yet successful VDC / BIM project.

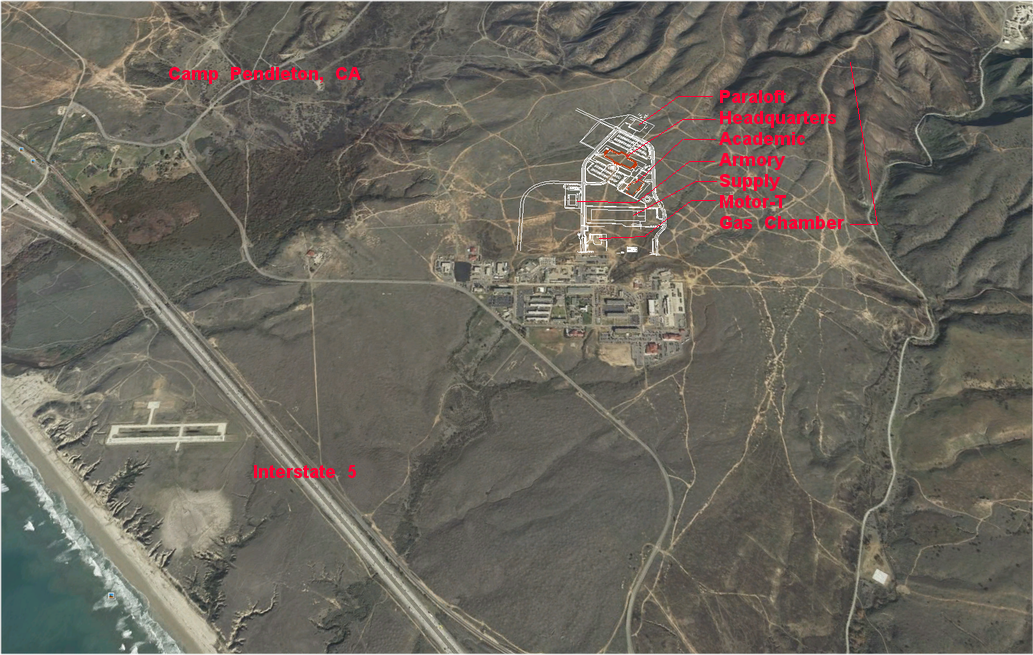

Marines Special Forces Complex - Camp Pendleton California

Select graphic for larger view.

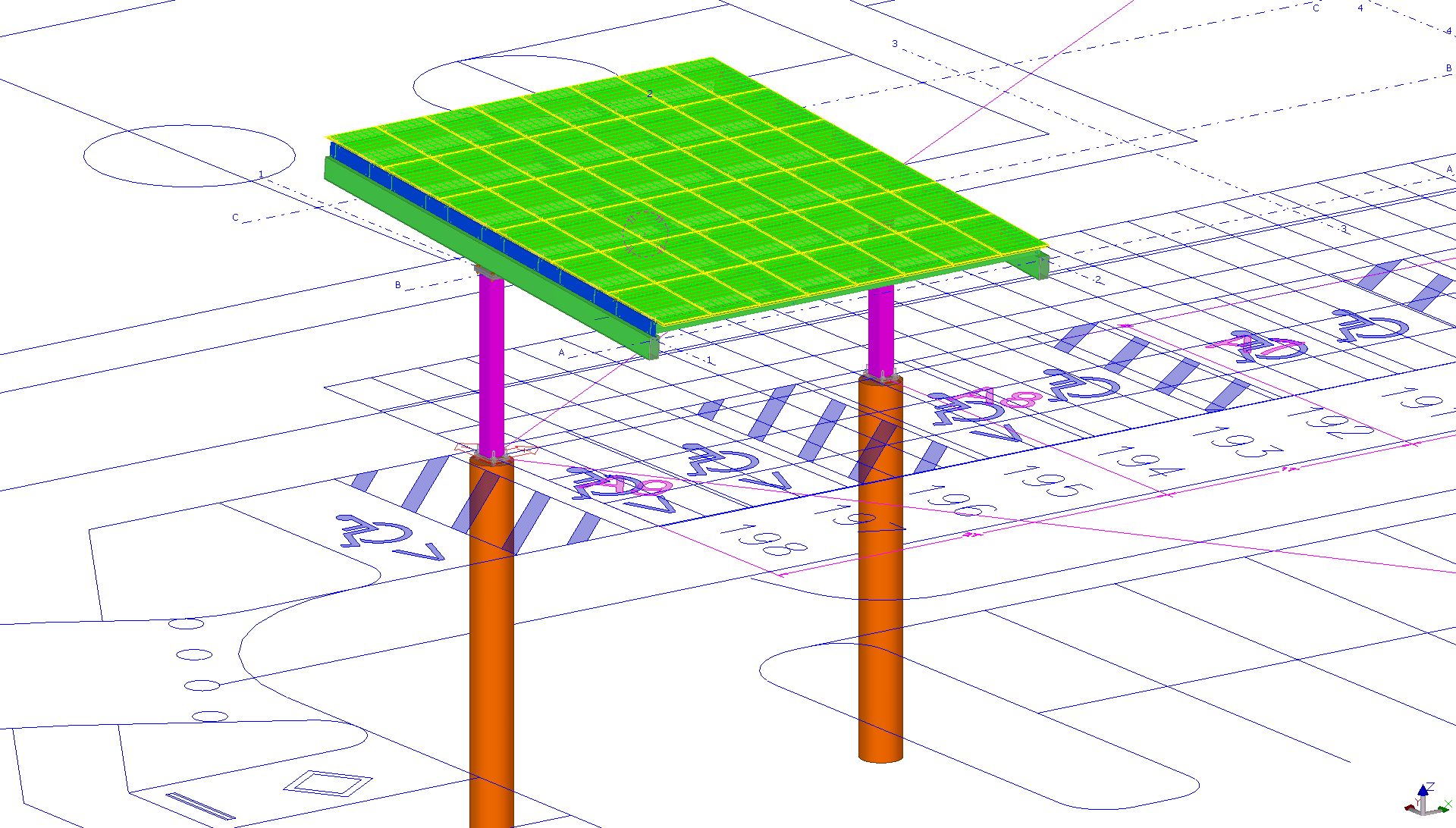

In March 2009, LucroSol secured a contract for VDC, BIM, IPD, steel fabrication and erection, metal deck, misc metals, and shop drawings on six Marine special forces (MARSOC) buildings, equaling 222,200 square feet at Camp Pendleton, California. Our scope included; improved construct-ability, and safety, plus reduction of schedule, RFI’s and Change orders, with emphasis on elimination of construction rebuilds. To accomplish this we created and incorporated a client specific Virtual Design and Construction (VDC) process.

The MARSOC project consisted of six buildings: - Headquarters - Supply - Academic - Paraloft - Armory - MotorT For cost effective and accelerated construction all the buildings except Supply, used a custom engineered steel truss and deck composite roofing system. Headquarters is a two story building and for the second floor uses a concrete composite deck supported by steel beams. The roof system for Paraloft, Academic, and MotorT use bar joists and steel truss & beam supporting a steel deck. All the roofing is standing seam metal roof. All these building required high quality structural steel shop drawings provided by Lucrosol. In addition to the structural steel and misc metals contract Lucrosol was asked to coordinate the entire project.

The structural engineer used a software product called Tekla for the engineering models, while the Mechanical and Electrical contractor used AutoCAD MEP a 3D product. The Plumber used 2D AutoCAD and the Fire sprinkler contractor used CADpipe. LucroSol took everyone’s 2D & 3D design and combined them into one model, a master digital prototype of the building. In many cases the firm created 3D drawings from 2D plans, rerouted HVAC wet and Dry and returned the MEP drawing to their owners for final shop drawings. We created a written specification to determine the modeled features that affected construct-ability, like the reflected ceiling plans, walls, soffits, bracing, and hangers. Once the entire building was coordinated, everything was built without conflicts or clashes the subcontractors would order and prefabricate their materials based on the revised drawings.

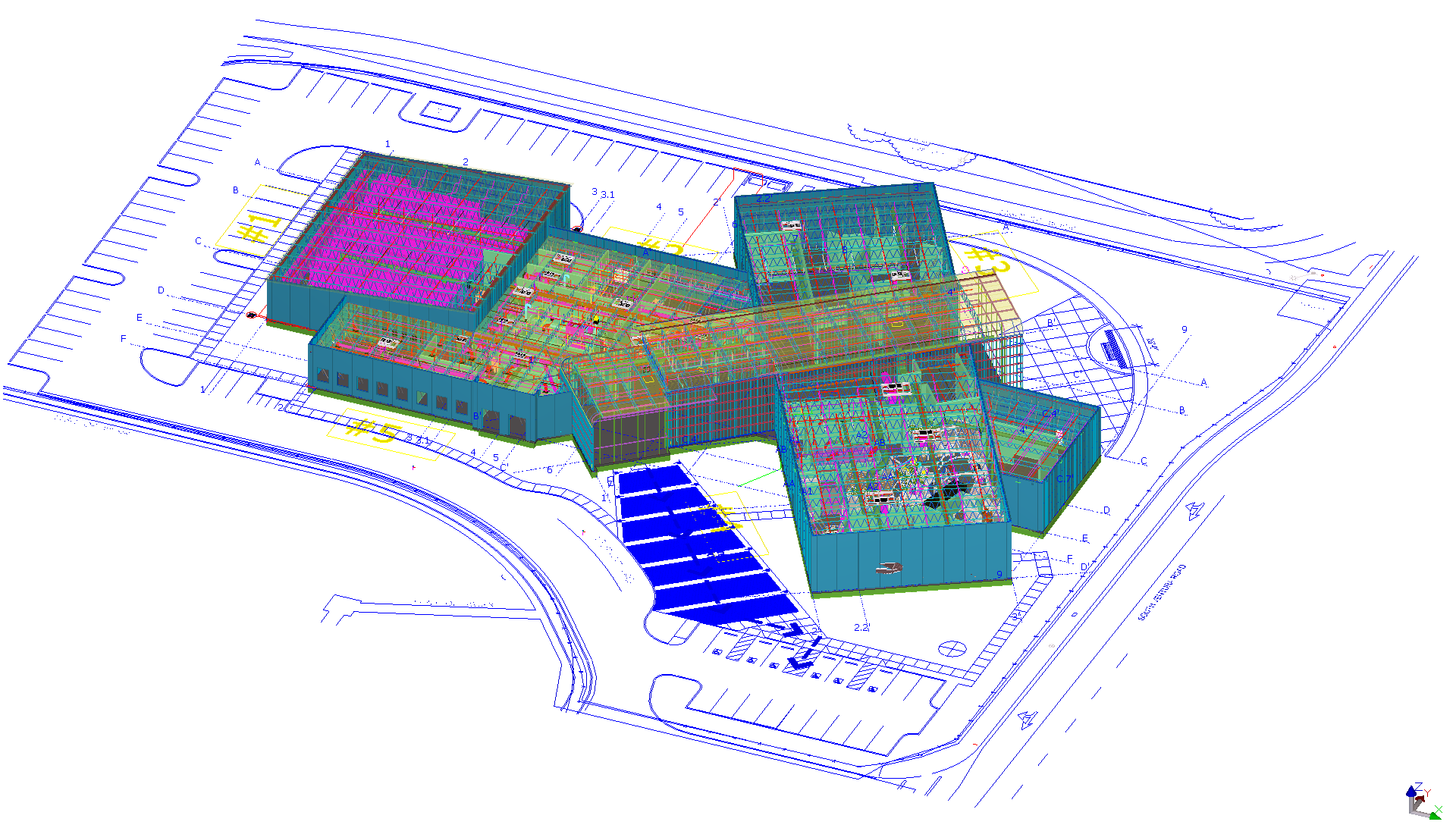

Seabee Museum - Port Hueneme, California

Select graphic for larger view.

In September of 2009, LucroSol secured a contract for structural steel, fabrication, erection, shop drawings, metal deck, and misc metals for the new Seabee Museum on the US Naval Base in Port Hueneme, CA. To provide maximum value to the US Navy, and Seabee foundation, and innovative building system was selected by the prime general contractor (RQ Construction who is partially owned by DPR Construction).

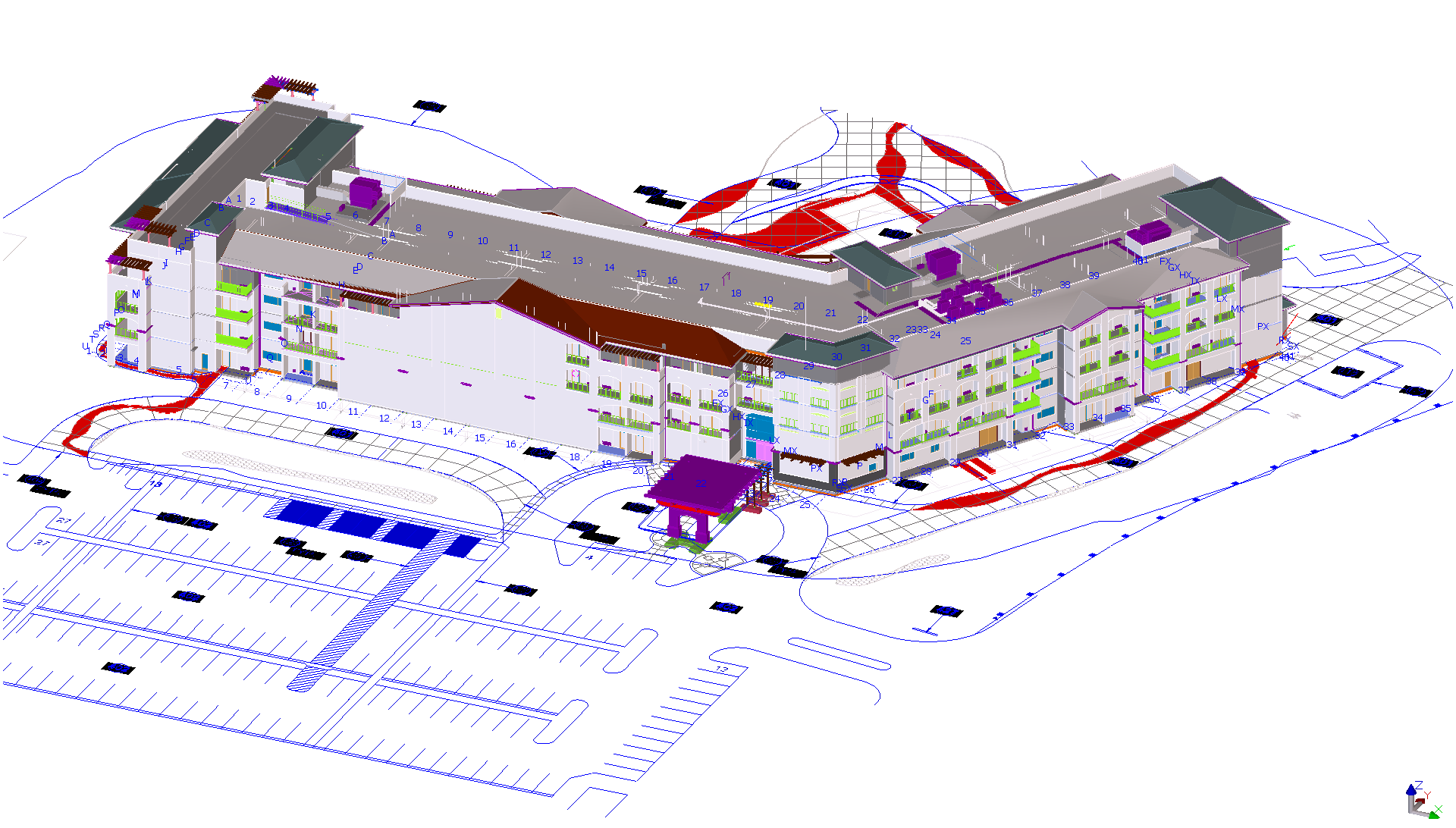

Naval Lodge Coronado Island California

Select graphic for larger view.

In November of 2010, LucroSol secured a contract for structural steel, fabrication, and erection, of a 166,000 Sq.Ft. oceanfront hotel/apartment Naval Lodge on Naval Air Station Coronado Island, CA. To provide maximum value to the US Navy, the innovative ConxTech building system was selected by the prime general contractor at LucroSol’s recommendation.

Veterans Assisted Living Facilities - Fresno, California

Select graphic for larger view.

In May of 2010, LucroSol secured a contract for structural steel, fabrication, and erection, of a 91,000 Sq.Ft. central plant and central services building, part of the Veterans Home in Fresno, CA. The central plant was typical filled CMU and structural steel, with metal deck covered by standing seam metal roof. Central Services is a two story structural steel metal deck and curtain wall structure, covered with a standing seam metal roof. more

Solar Array Camp LeJeune, North Carolina

Select graphic for larger view.

In July, 2011 LucroSol secured a purchase order to provide structural steel for a Solar array canopy system located in Marine Base Camp LeJeune, North Carolina.

VA Hospital Seismic retrofit Long Beach, California

2003 our innovation, design and execution of a seismic retrofit on a working hospital saved 4.5 million dollars. Along the way we overcame fastener installation issues Hilti engineers were unable to solve. Pictures of Hilti super rod and RE500 epoxy applied upside down in concrete.