Seabee Museum - Port Hueneme, California

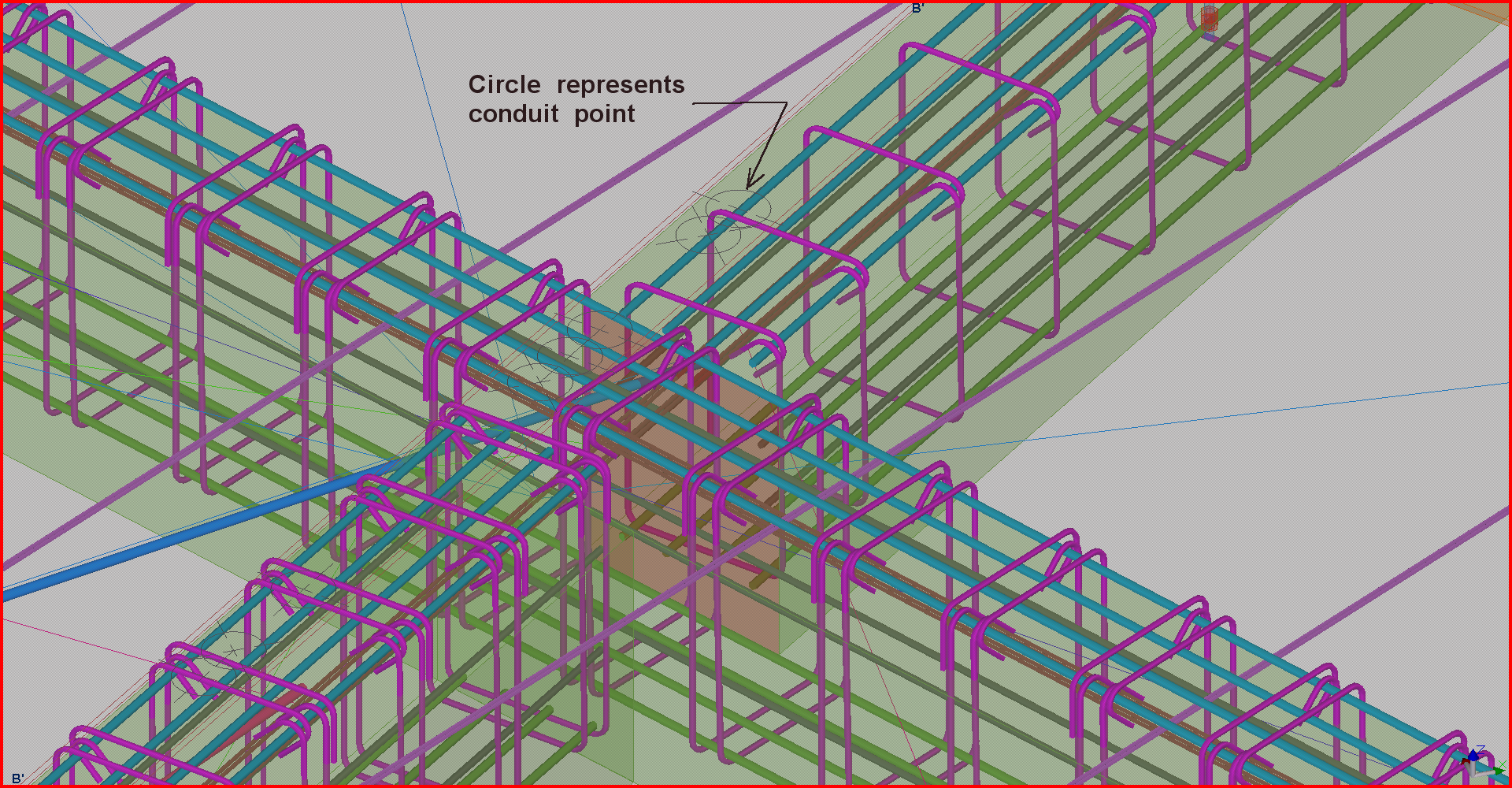

Final coordination of conduit stakeout used 2D of electrical & exterior panel shop drawings

In September of 2009, Lucrosol secured a contract for structural steel, fabrication, erection, shop drawings, metal deck, and misc metals for the new Seabee Museum on the US Naval Base in Port Hueneme, CA. To provide maximum value to the US Navy, and Seabee foundation, and innovative building system was selected by the prime general contractor. The system of metal stud and concrete panels know as ecolite, were used to increase quality, speed construction, and improve safety. This project required a high degree of underground and in slab coordination to accommodate the fixed metal stud locations in the eight foot wide panels throughout the building. Lucrosol worked directly with the subcontractors locating rebar, post tension cables, electrical conduits, structural anchors and hold down locations. Most of the critical items in the slab were located with Trimble total station using coordinated 3D model information. The results were astounding, with only one stud being notched to accommodate an electrical conduit at slab edge.

Using the subcontractor 3D and 2D shop drawings, design drawing and equipment submittals Lucrosol coordinated the following systems: mechanical, plumbing, gas, electrical, structural, light gauge metal stud, architectural, exhibits, drop ceilings, lighting, hangers, shop drawings, crane locations, materials staging locations, and many other daily activities.

To bridge that “last one hundred feet”, or provide 3D coordination information to the superintendents, and subcontractor foremen, Lucrosol provided a powerful computer with a large high resolution monitor, speakers, and high resolution webcam, completely configured with all the necessary software to:

(One) Conduct collaborative internet based meeting with outside consultants, subcontractors, engineers, suppliers, in-house personal, and others

(Two) send and receive email, attachments, connect to ftp locations, and exchange time sensitive construction information

(Three) Conduct daily Flow and Problem Prevention scheduling meetings via the internet

(Four) View 2D and 3D AutoCAD based dwgs, Tekla 3D drawings, 3D Revit drawings, PDF and other construction documents

(Five) permit any subcontractor to view in 3D the area of work they were performing so they could consider the other trades.

Lucrosol reduced the cost of the project allowing the owner more features and museum items for the original contract price. The construction schedule was reduced by three months using a combination of coordinated panelized structural systems, prefabricated MEP & Fire trades, and precision stakeout using Trimble total station.

One

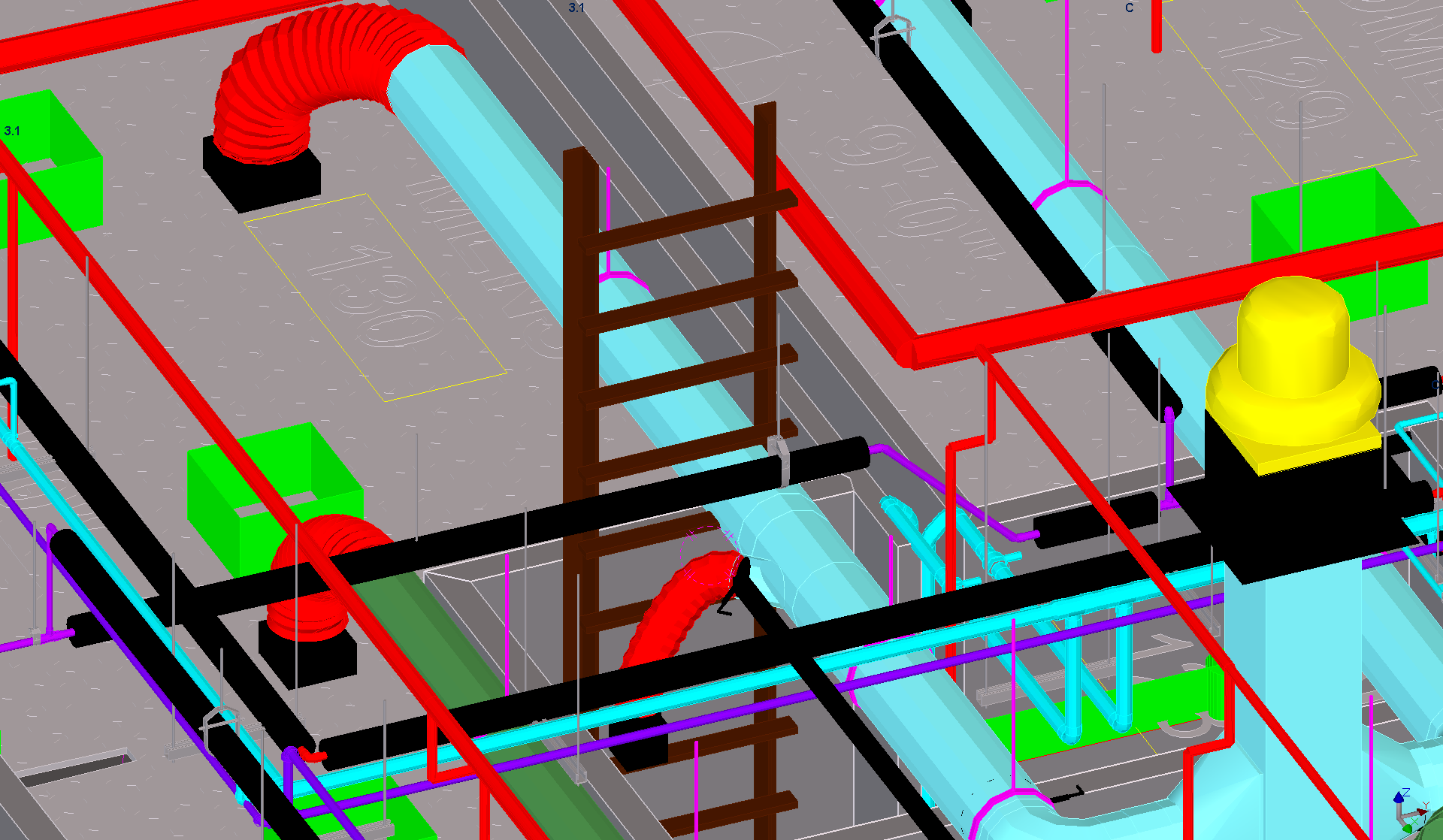

It's always the simple things, like access - note ladder in duct

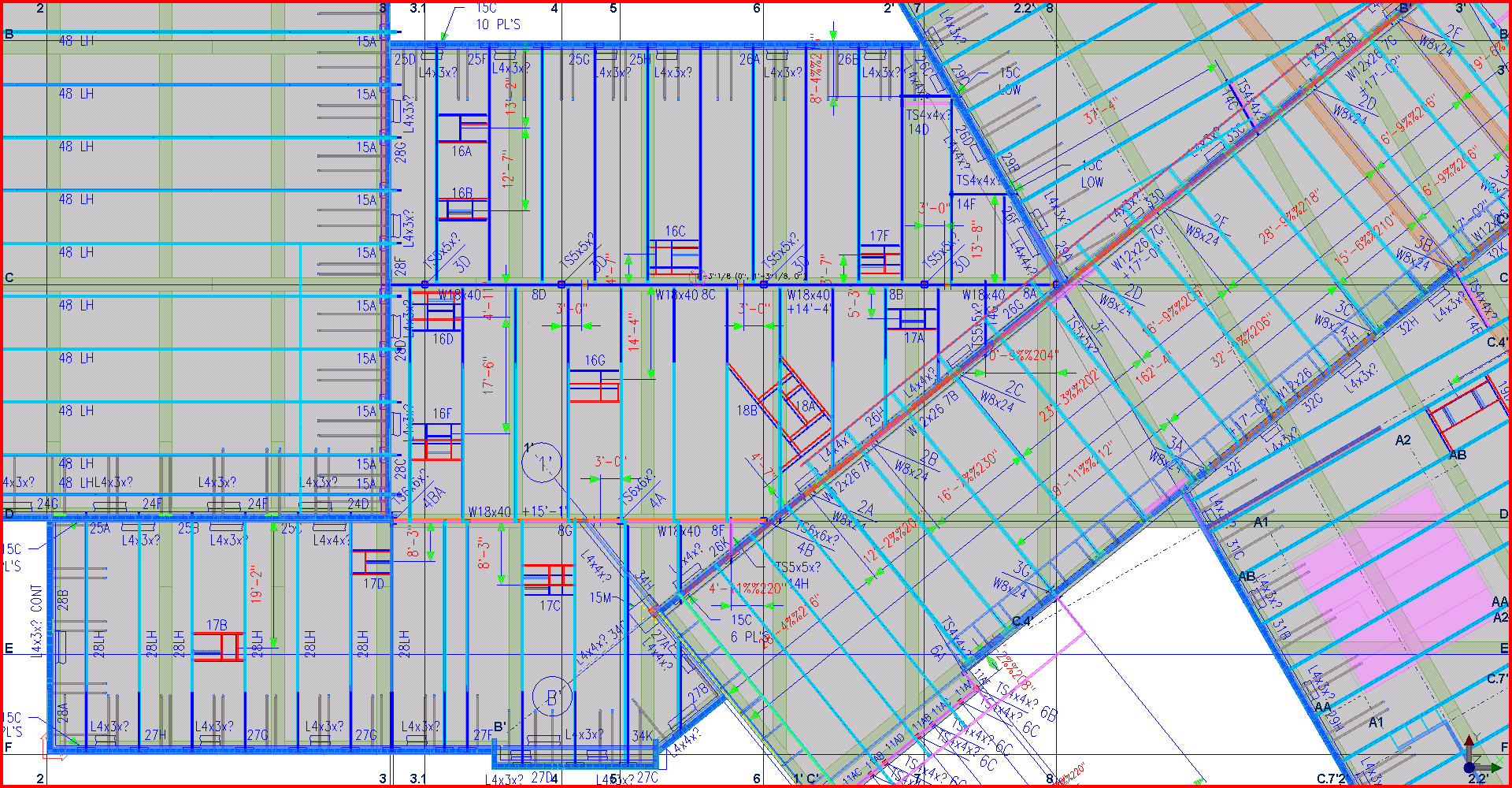

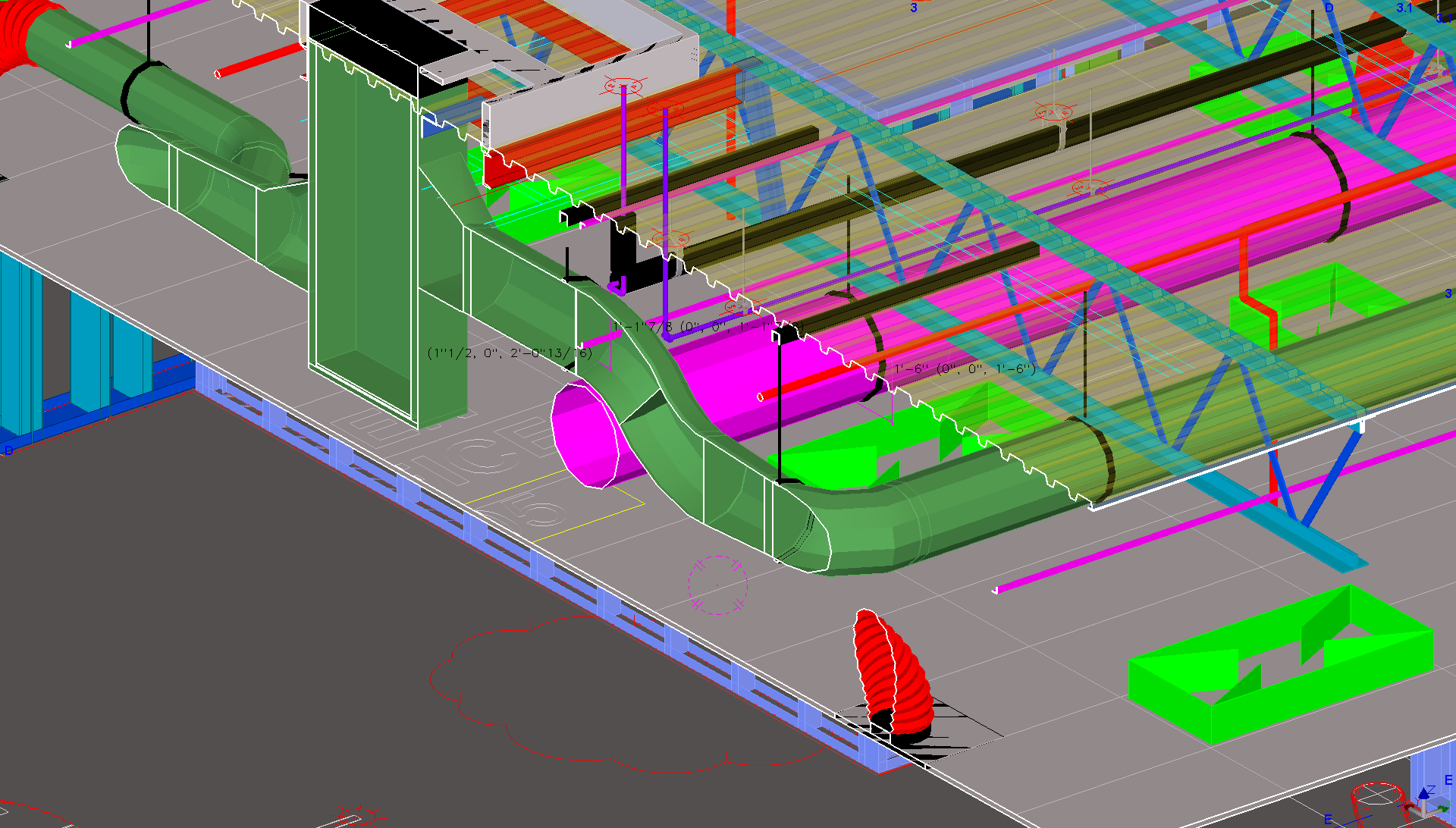

Final shop vs engineering structural models

Note the red vs blue - final shop drawings for fabrication did not match coordinated model.

Cross Sections, slices, as a tool

Note pink structural element in duct, 2D location of pipe penetration symbols