July 09, 11:00 PST meeting with Nate Henshaw, Nathan Vigil, Kenneth Leslie, Shyam Telikicherla

Post meeting revisions:

July 11, 2021 Added intel lessons learned link

Agenda:

-Introductions: All

-Purpose: Nate

-Review the detailed proposal: set up, its benefits, costs and trade integration plans: Greg

Minimal pilot setup consists of me, a field trade with fall protection certification, a trade modeler/coordinator for the coordination portion. The fabrication and installation portion requires a trade to fabricate a few spools and hangers, transport and install. Note plastic pipe is fine to use for pilot.

Benefits: lower cost, duration & resource requirements.

Costs: Pilot at $25,000 - $23,000 and shall be refined to a not to exceed fixed cost when we determine scope, and location.

Trade integration plans: Low key awareness process after pilot has metrics and lessons learned with projected benefits, costs and field metrics.

-Next steps:

-Nate will review with Intel team and do roll up, recommendations.

-Circle back with Greg on next steps.

Points, Narrative, References

Points:

Want to stress the point of thoroughly investigating and comprehensively understanding the improvement I am suggesting.

A core issue is any cost a trade incurs providing services to Intel is passed to Intel.

This process I’m proposing is based on sound logical Intel BIM environment related experiences.

No anecdotal data is in use and projections are based on the pilot conducted in Fab 42.

Plainly stated, only hard data will discourage me from continually suggesting easier more cost effective ways to construct and equip a fab.

My agenda is singularly focused on reducing durations, and construction costs while improving quality.

Narrative:

The love of solving a significant Intel construction problem drives me to keep asking for this a second study using metrology to directly create 3D coordination models of pipe, conduit, as-builts, and any other measureable item the construction team needs to complete their work.

We’d use a light, 6.17 lbs, remotely controlled camera, laser scanner, a survey instrument, to collect geometry in areas a laser scanner cannot access to address one problem currently experienced globally by Intel construction services. Namely providing trade detailers and BIM/VDC centric staff access to as-built conditions in particular subfab areas.

Now if Intel has taken the idea along with the data validating the initial concept collected in Fab 42 I am not aware of it. Intel paid $5000 for the expenses of that field trial through Hensel Phelps.

If Intel has data disproving the viability of my proposal, no one has shared it with me.

To date the data collected in Fab 42 has not been refuted, nor disputed.

I’m requesting second field trial be conducted to further refine the actual value in dollars the solution is projected to save Intel globally.

A follow up field trial contains these elements:

- A person with fall protection certification places the 3D Disto on a piece of unistrut using a mechanical or magnetic mount.

- A second person records measurements using a tablet or notebook computer while on the subfab floor.

- Those measurements are emailed or texted to a detailer somewhere.

- Those measurements are converted into a 3D model of pipe, conduit, hangers or other existing or proposed object.

- The 3D model is submitted to the 3D federated model and goes through the coordination process ending in eventual approval.

- The approved centerline geometry is laid out and fabricated in an off-site or on-site room using the 3D Disto to provide the layout of the item – thus eliminating the creation of a shop drawing.

- That completed section of pipe or other item is then transported to the subfab and installed.

We record the process, what resources were required, what labor was used, and project the time and cost against the existing process used.

Reference:

https://lucrosol.com/node/52 generally outlines part of the problem/solution, notably trade designers require accurate and timely subfab conditions to perform their job well.

https://lucrosol.com/node/42 the 2018 proposal which was partially completed in September 23, 2018

https://lucrosol.com/files/Intel_Pilot_Report_2018.09.04.pdf is the Fab 42 report outlining the process & results of our initial pilot.

https://lucrosol.com/node/83 graphic of Point of connection and utility route mapping conducted in Fab 42.

https://lucrosol.com/node/29 the detailed overall conceptual theme of transforming Tool install with examples.

wiki.lucrosol.com Intel lessons learned link

Greg with Stanford CIFE professors

Spreadsheet (select to download)

Movie overview: How to use spreadsheet

Movie explaining how to use Return on Investment calculator in spreadsheet. If you can not view this video please; 1) enable JavaScript, and 2) consider upgrading to a web browser that supports that supports HTML5 video. Select for HTML5 video support

Added Week of July 4th 2021

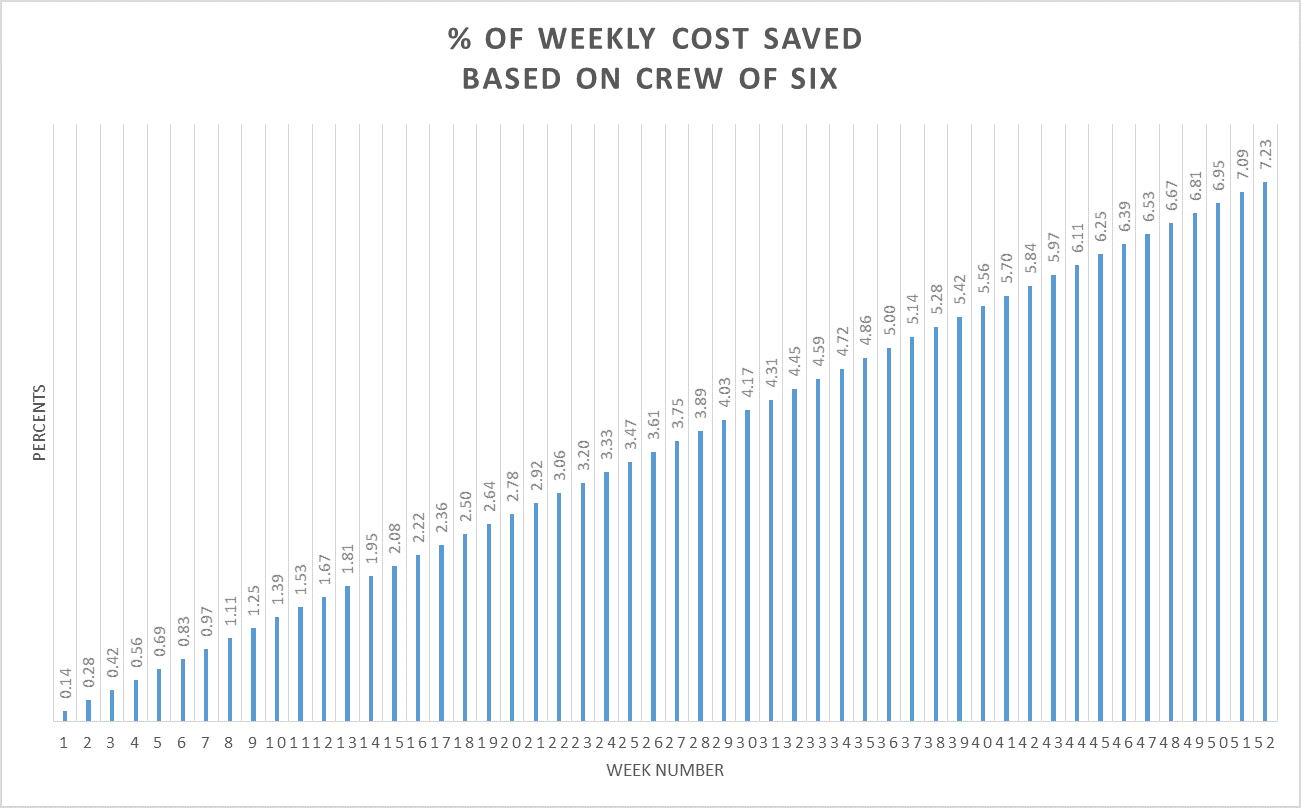

Percent saved using 30% of two billion presumed to be labor cost, using six person crew

Brief description of sheets in Workbook

Adsk_ROI sheet

The Return on Investment formula provided some time ago by autodesk.

Wholely inadequate for any meaningful analysis.

ScanData sheet

Analysis of laser scanning file format sizes and costs

ScratchPad

Just that a place I use for temp calculations

Top 85 VDC sheet

Eighty five of the top contractors per Engineering News Record a few years ago.

Charts

ManCount sheet

Somewhat detailed analysis of a Tool Install ramp man counts along with tool complexity

and number of spools that need to be made and installed.

MetricsOfSomeTools sheet

Detailed analysis of types of process pipe in tools, gets more granular as

to the exact sizes and counts along with material types.

ManualSpoolDwg sheet

Analysis of time it takes to detail out shop drawings so you can produce

a spool.

Meeting_Agendas sheet

Analysis of how much meetings cost Intel vs the actual value that they provide.

CoordinationMeetings sheet

Analysis of cost to Intel on the number of coordination meetings they hold.

Ocotillo sheet

Analysis of trade contractors in chandler, their performance levels, cost, staff, capacity

Software in use.

Source sheet

Data used on lookup tables

Israel sheet

Few metrics on past programs

Field sheet

Data on field issues, office issues, problems and their impacts along with some costs

Risk sheet

Analysis on risks associated with any TI program, labor and cost projections.

Technology sheet

Listing of metrology and software costs

API Tracker sheet

Just a data capture

AT960_costs sheet

Projections on cost and usage scenarios to understand value

3dpointcost_old

Analysis of how much each usable coordinate of information really costs? Various means of data collection are represented.

Tech_Summary sheet

Measure vs model production study to see possible cost benefits

Large Semi sheet

Chart of the semiconductor players

2021_proposal sheet

Analysis of costs to monitor entire subfab with devices, or some solution that would allow constant production and facilities observations.

Model_Fab sheet

Study to see what it would cost to model the entire subfab along with how long it might take.

Working Estimate 2020

Generally some costing to deploy a metrology solution.

WW_Progress sheet

No clue

3D_DistoTeam sheet

Scratch pad on cost to deploy distos.